Domestic Wood Pellet Boilers

Information on how biomass heating systems work, the products we supply, and the costs.

How do biomass boilers work?

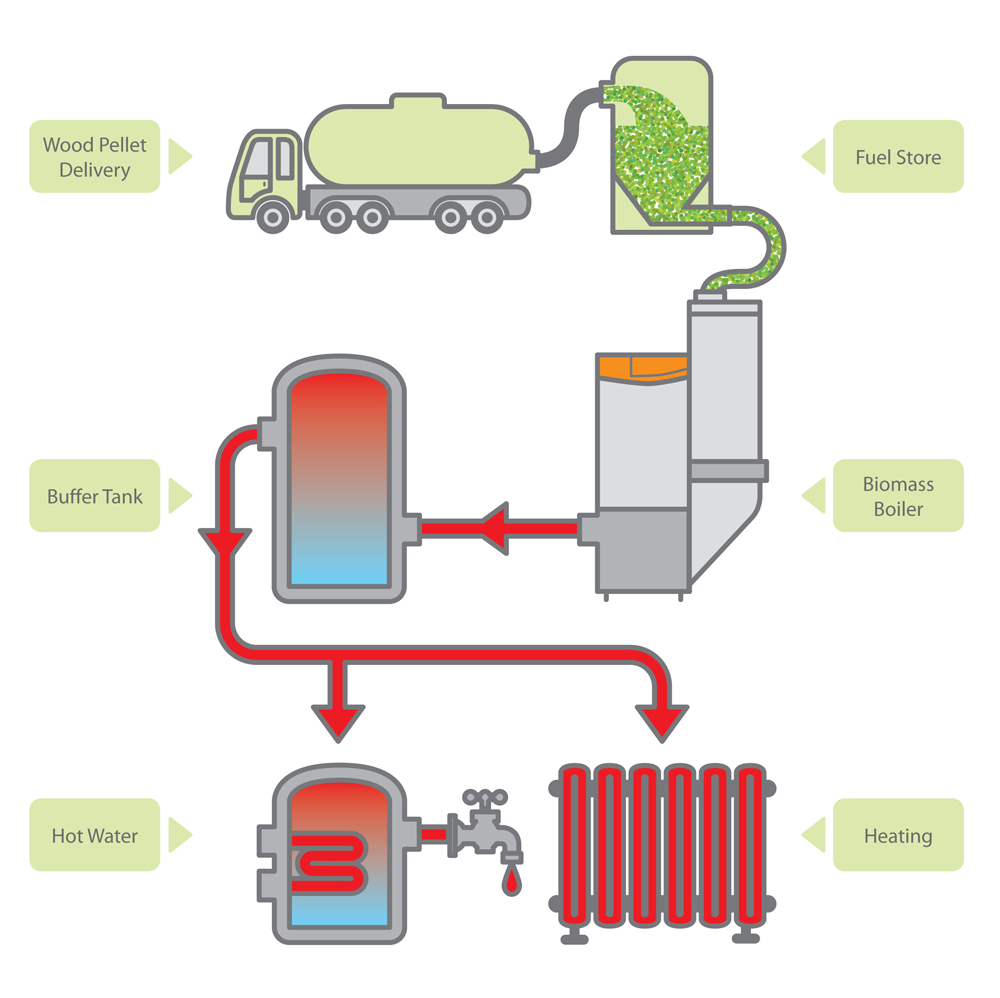

Biomass boilers work exactly like conventional fossil fuel boilers except that they burn biomass fuel, most commonly wood pellets. The pellets can be delivered in bulk by tanker where they are blown into a storage hopper or tank, or they can be delivered in bags.

The wood pellets are fed automatically from the store via a vacuum system, auger (screw mechanism), or gravity. Smaller fuel hoppers integrated into a biomass boiler may be filled automatically from a bulk fuel store or manually from bags every few days, or possibly more frequently during the winter months.

Pellets are burned within the boiler to generate heat in the same way gas or oil burners do. The heat generated is used to heat water which is then used to provide hot water and heat in your home. A thermal store or buffer tank located near the boiler enables the boiler to work most efficiently if sized appropriately. Biomass boilers can usually be connected to your existing heating and hot water systems.

Highly automated, Okofen boilers require little intervention from the user, and can even be easily controlled over the internet – from the comfort of your armchair or from another country! An external ash compacting unit enables the boiler to operate smoothly for many months before the ash pan simply needs to be wheeled outside and emptied.

The OkoFEN Pellematic heating systems are both flexible and adaptable. If you add an extension that requires extra heating, or your insulation is enhanced, a Pellematic boiler can adapt to this with only minor adjustments, ensuring the perfect amount of heat is always available.

Their engineers are focused on continuous technological advancement which has led to breakthroughs in optimised combustion, efficient condensing technology and user-friendly systems like the Pelletronic Touch heating controller.

Talk to us to find out which biomass boiler will best suit your needs.

The Bioclass NG boiler’s fully automatic burner and heat exchanger cleaning system provides comfort and convenience to the user. The cleaning of the burner (GRINDER system) is specially designed to treat high strength and unburned ash (silicas) to ensure both durability and minimal maintenance of the equipment. The Grinder system is designed to work whilst the boiler is firing ensuring the boiler is working at the optimum at all times.

The electronic controls provide the exact amount of air depending on the amount of fuel to achieve the required temperature. This creates unbeatable burning performance especially at reduced power levels. By having the possibility of working at low power, constant on/off cycles are reduced, avoiding energy losses when the boiler stops and giving the possibility of being installed even without a buffer tank.

Domusa’s competitive price policy along with the highest technical performance ensures that the annual savings compared to the use of other fuels, quickly offset the investment of the initial purchase.

Fully automated ignition, and automated cleaning of the burn grate and heat exchanger makes these boilers easy to live with and very low maintenance.

Biotech use the revolutionary Dual Combustion Control (DCC) ® technology throughout its range of pellet boilers. The DCC technology uses a combination of air flow sensors to automatically detect the quality of the pellet fuel and adjusts the combustion parameters accordingly, resulting in up to 30% increased efficiency of pellet consumption as well as reducing emissions.

Biotech boilers have been independently tested at 96.3% efficient, which is exceptional for any biomass boiler.

Biotech have a full range of boilers that allow us to provide the best boiler for your needs from a smaller home through to larger properties or even hotels with high heat and hot water demands.

MCS approved

All our boiler products are accredited to the Microgeneration Certification Scheme, or MCS, in the UK to ensure that consumers are able to access UK government financial incentive schemes for renewable energy.

Having an MCS approved biomass system is a quality criteria for the government’s RHI funding.

To find our more about opportunities for grants and interest free loans for renewable energy read our pages on funding.

How much does it cost?

Several factors impact the cost of installing a biomass boiler, in particular:

- How much heat your home needs determines the size of your boiler

- What volume of fuel can you store? – large bulk deliveries are cheapest but need larger fuel stores

- Do you have an existing hot water tank that can be reused? Perhaps a buffer tank with hot water coil would be more efficient?

- Is your heating system suitable for connection? Most wet central heating systems can be connected, but the considerations for underfloor heating are different to those for radiators.

Bear in mind that 85% of the life cost of a heating system is in fuel – so consider how your fuel will be sourced, delivered and stored to reduce whole-of-life costs.

The space required for a biomass boiler is greater than equivalent fossil fuel boilers, and you may require building work to ensure you have the space for your boiler and wood fuel.

Speak to an Expert

Call us free on 0330 22 33 868 or email us your questions.

How we can help

We know that the installation of a new heating system is a major undertaking and requires significant consideration. To help you through the process we can:

- work out how much money a biomass heating system could save you.

- support you in applying for funding to assist with the cost of installation.

- design a biomass heating system that will be most effective for your home.

- manage the ongoing maintenance and servicing requirements of your boiler.

If you invest in a well-made biomass boiler system you can expect low maintenance for many years.